The black box from a cargo ship

I will tell you about my experience repairing a cargo ship as a naval Engineer. Some months ago, you could read in the local newspaper Málaga Hoy that a large cargo ship was...

Filter by Category

Filter by Author

I will tell you about my experience repairing a cargo ship as a naval Engineer.

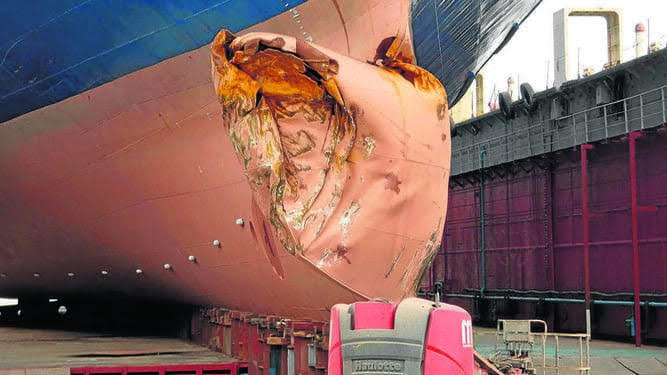

Some months ago, you could read in the local newspaper Málaga Hoy that a large cargo ship was approaching Málaga after a major accident it had suffered in its front part.

It was the cargo ship Integrador with a Panamanian flag, the capacity to transport 1000 cars, and belonging to RORO Shipping Company, which operates with eight ships in different countries. Those responsible for it proceeded to contact us (Andalú Sea Robotic Submarine) so that upon arrival, the hull could be examined with the ROVs and, in this way, observe the dimension and depth of the damage caused during the accident.

I haven’t posted anything until now, as this work has involved quite a bit of complexity, from decrypting and obtaining the black box to the final launching of the ship and a lot of logistics.

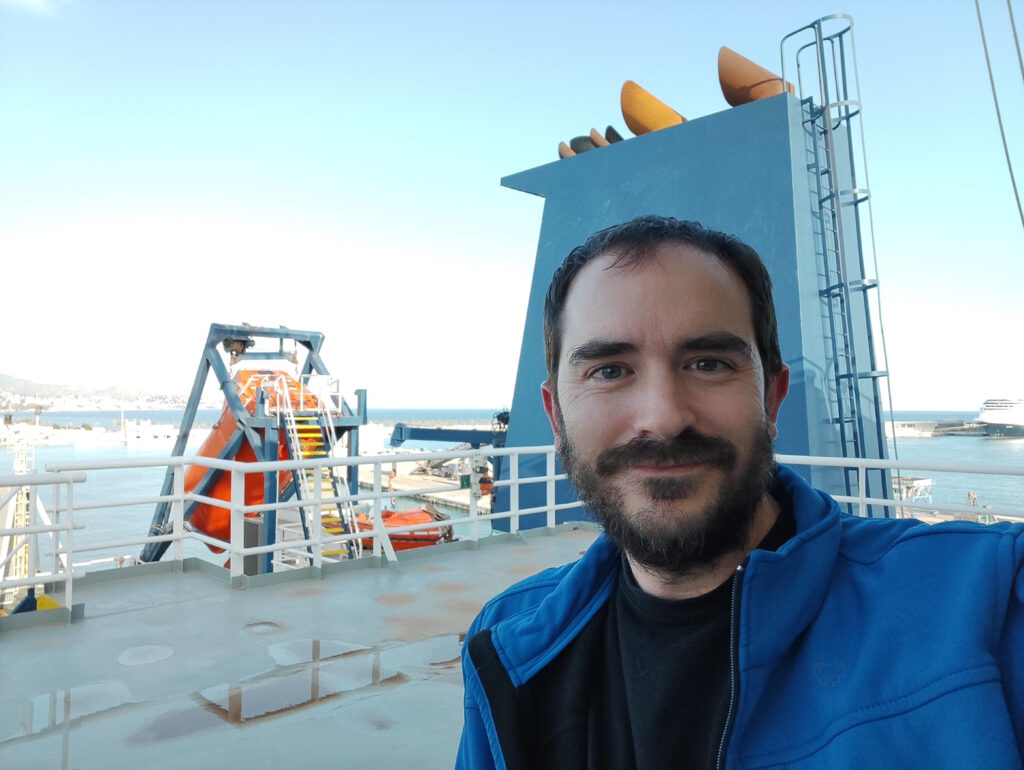

When the ship entered the dry dock at the Mario López shipyard in the Port of Malaga, we extracted the data from the VDR (black box) of the ship and gave the information found to those responsible for it.

The company hired us throughout April and May to carry out diagnostics, maintenance, and updates of the electronic systems of the ship’s bridge.

The list of performances was not small:

We worked day and night.

All the work was carried out within the established deadlines, and the launch day arrived. That day I was finishing the commissioning of the BNWAS motion sensors, and I couldn’t get out on time, so I was on board during the launch, which was a very enriching experience. The outstanding work of the pilot, the captain, and all the crew who proceeded to supervise and carry out the necessary manoeuvres for the launching, transfer to the lifting dock, and later it is mooring, with the added difficulty during the approach and mooring, because the vessel still did not have engines or operating reels, since the maintenance, repair and improvement operations would continue in the Levante dock moored at the port.

Days later, the ship left the inlet of the port of Malaga to anchor and test the latest improvements to leave for distant lands. However, one of the control systems in the engine room produced an error, and the ship had to return due to a broken motor control system since it could not manoeuvre.

Again we were notified to proceed with the repair of said systems. In this process, it was necessary to extract and duplicate the memories of the motor control systems.

The engine room of a ship of this type is simply indescribable. Everything is big, big engines, and multiple cabinets with interconnected and redundant systems. Each control part is differentiated. So we had to review practically everything.

Finally, after supervision of the start-up of the engines, everything was successful, and without further problems, the ship departed for its new destination.

It has allowed me to meet great and professional people on a technical and personal level. We have shared a table with the crew and dozens of coffees. I still remember the day we all had a snack together with sweets from Malaga.

It has also been an honour to have received recognition from the owner and CEO of the RORO Shipping Company, Mr Gabriel Kaklouk, for our work.

After finishing the operations, they told us they were pleased with our improvements. However, we then knew that they had called up to 5 companies before ours to repair some of the systems without any of them finding the right solution to control the ship systems work correctly. Some even refused to touch anything seeing the high complexity of such systems.

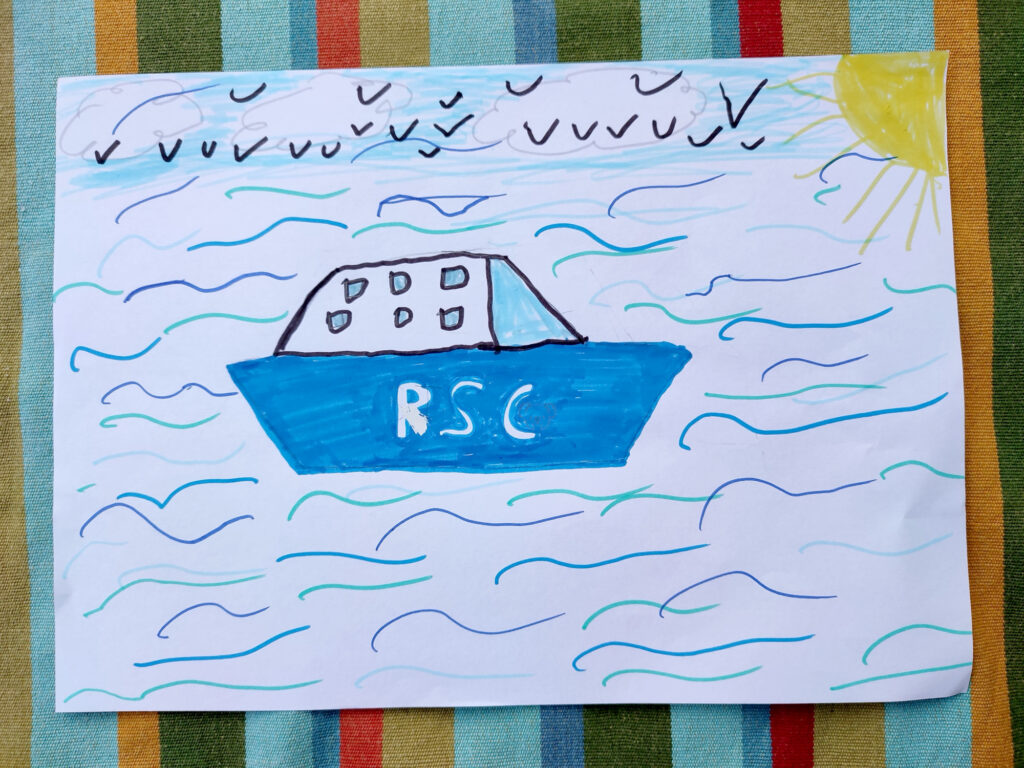

It has been a strenuous job due to its haste and the speed required to carry out all the operations, and since I have been combining all these tasks with my daily work, my wonderful family has supported me during these two months. Our children have been following all the operations all this time, asking us to see the ship and asking dozens of questions when they saw the photos. A Trace of it leaves this drawing:

In my last post, “How I designed the frame for my Underwater ROV“, I gave all details about the design I used for the frame for Alioli Underwater ROV. In this post, I...

In my last post, “Underwater Alioli ROV“, I shared all the information I got from the Internet to build my Underwater ROV. In this post, I will explain how I made the...

Draw… the best!

Congrats, very interesting and crazy opportunity.

I like it.